Always the best view

Thermally insulated window system with basic depth of 65 mm; also available with concealed drainage or outward opening, or internal flush-fitted vents.

Innovative foam-filled insulated bars. Large volume centre gasket. Glazing gaskets with fins. Insulating bars in vent with hollow chambers. Klassifikation in accordance with DIN EN ISO 10077.

Outer frame profiles with face width from 51 mm. Reduced face widths due to narrow double-vent profiles.

Mullion profiles with face width from 76 mm t0 250 mm. Flexibility in design, different colors outside and inside. Also available: feature glazing bead that is mitre cut on all corners. Additional design series available, e.g. RL = Residential Line and SL = Soft Line. Burglar resistance up to WK3 in accordance with DIN V ENV 1627. Concealed Schüco AvanTec system fittings up to 130 kg. Vent profiles for Schüco TipTronic, Vent weights up to 160 kg. Concealed drainage possible. Solution for easy-access patio and balcony door in side-hung, turn/tilt and double-vent design. Crank-operated turn/tilt solution for large, heavy units (Schupo Window AWS 70.HI) Insert outer frames for fitting into facade rebates. System testing with classification in accordance with new European standards.

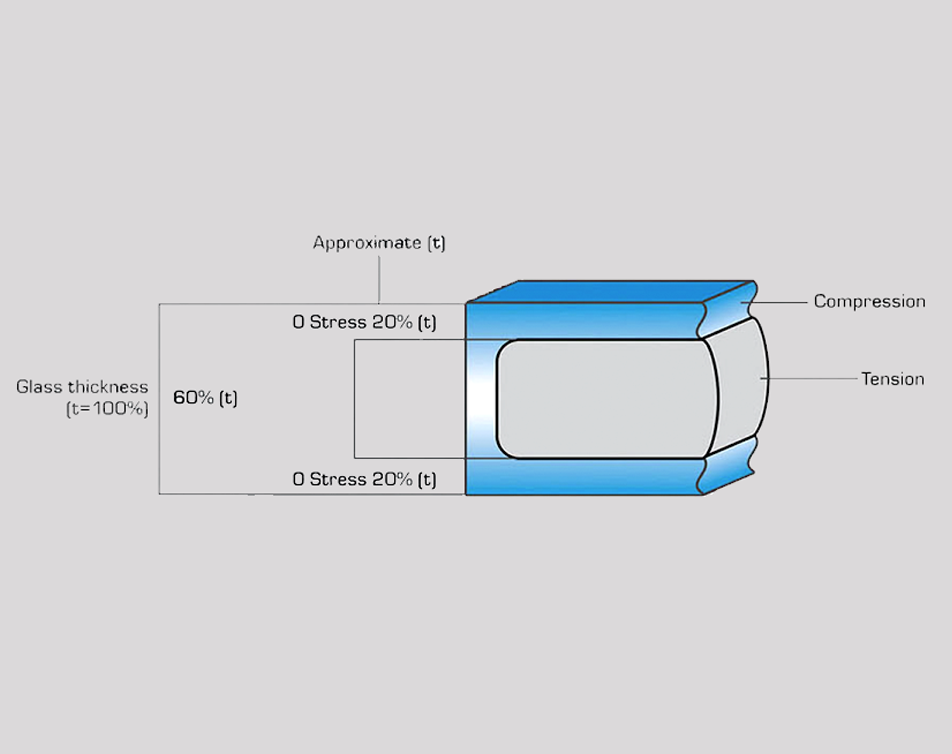

Tempered glass is about four times as strong as annealed glass of the same type and thickness. When brocken, tempered glass fragments are usually relatively small and less likely to cause serious injury, so it is classified as a safety glass. Architects may specify tempered glass fro commercial or architectural projects, however, tempered glass may also be heat seal tested, in order to minimize the risk of spontaneous breakage. Tempered glass cannot be cut or drilled after tempering and any alterations such as edge grinding, sand blasting or acid etching will weaken the glass and can cause premature failure.

Standard laminated glass consists of two or more panes of glass that are permanently bonded together by heat and pressure with one or more plastic interlayers of polyvinylbutyral (PVB). Normally clear, both the glass and interlayers can be manufactured in a variety of colors and thicknesses to provide a decorative appearance. Laminated glass is suitable for use where safety glazing is required by local Building Regulations and Standards. When broken, the fragments usually adhere to the plastic interlayer and the risk of injury is reduced when compared with annealed glass. Laminated glass may be manufactured with heat strengthened or toughened glass to provide additional strength if required.

Production lines for PVC windows has been completely computerized automatic latest technology. Types of machines are from German manufacturer ELUMATEC.

The technology of glass processing for windows is realized through the most modern machines LISEC, which does the whole process of working in computer, with European standard.

Designed production capacity for IZO glass is 100 triple glazed IG Units per day, and 120 double glazed IG Units per day.

We will process your request promptly and will get in contact with you as soon as possible

CONTACT HERE